JIS Die Springs (Metric)

Features:

Die springs are industry-standard springs designed to support high loads in limited space. These are often used in precision machinery such as die punching, die casting, or die injection. MK SPRING stocks springs made to US and Japanese standards supporting all ranges of light to super-heavy loads.

JIS Die Spring Spec Sheet

(JIS B 5012)

Made in Taiwan

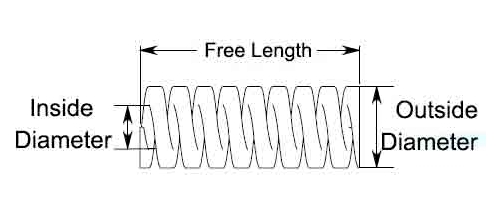

Engineering schematic

Allowable Tolerances

| Outside Dia. (OD) |

Inside Dia. (ID) |

Free Length | Load | |

|---|---|---|---|---|

| Less than 50mm |

More than 50mm |

|||

| +0mm -0.7mm |

+0.7mm -0.1mm |

±0.5mm | ±1% | ±10% |

How to use die springs?

- Determine the maximum stroke required for your application before selecting the spring.

- Preload each spring before installation to avoid premature failure. A general guideline is to apply a preload of 3–5% of the spring's free length for optimal performance.

- Ensure each spring fits correctly into its matching spring pocket and guide rod.

- Monitor tool wear : As punch tools are ground over time, the preload on the springs increases. To maintain consistent spring travel, make sure to grind the gaskets accordingly.

Deflection vs. Usage Frequency

(% of Free Length)

| Working Time/ Items |

0.3 million (%of free length) |

0.5 million (%of free length) |

1 million (%of free length) |

Max. Deflection (%of free length) |

| Lightest Load (YF Series) |

50% | 45% | 40% | Approx. 58% |

| Light Load (YL Series) |

40% | 36% | 32% | Approx. 48% |

| Medium Load (YM Series) |

32% | 28.8% | 25.6% | Approx. 38% |

| Heavy Load (YH Series) |

24% | 21.6% | 19.2% | Approx. 28% |

|

Super Load (YB Series) |

20% | 18% | 16% | Approx. 24% |